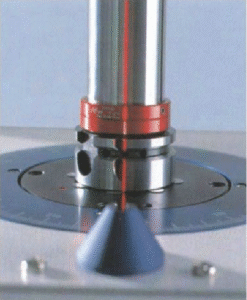

Er Spring Collet Chuck

Comprehensive inspection way of chuck

#7:24 taper precision ≤AT3And part of the standard size are tested by

standard inspection tools which made in Germany;

#Surface of the clamping inner hole is grinding by high speed inner-aperture grinder. and inspect by standard pneumatic measurement instrument; the big end contact area rate is above 90%;

#Shank thread is inspected with 4h level thread ring gauge. and the nut is inspected with 4H level thread plug gauge, the quality guaranteed;

§Run out of the inside shank Bone: <0.002(The length of the shank 100L)

#Coaxiality 5u:Shank run out≤0.002;

Equip≤0.005. The highest comprehensive run out point is no more than0.005(≤0.005mm collet clamping interchangeable with any integrated shank run out does not exceed the highest accuracy 0.008mm);

#Dynamic balance:We can do G2.5 20000一50000rpm according to clients demands.

Cryogenic treatment

1一1850 long cryogenic.nearly all of the residual austenite into martensite

2.Carbide precipitation of Nanoscale particles,increasing the hardness

and toughness 3.Reducing residual stresses

4.Wear resistance significantly improved

Thermal aging processing

20h long stereotyped thermal limitation removal

of grinding residual of grinding residual stress.